BISIC DESPREPTION OF HD786G

Load capacity★★★★☆

Wear performance★★★★☆

Speed performance★☆☆☆☆

Shipping distance★★☆☆☆

Product performance characteristics of OTR tyres Haida tires HD786G 12R22.5 mining tires

◆ Widened and deepened pattern design, excellent puncture resistance and impact resistance,

Longer service life.

◆The design of lateral grooves provides excellent grip and driving force. .

◆The bottom of the pattern groove adopts a convex-type anti-stone trapping design to improve the puncture resistance.

Effectively protect the carcass.

◆Using high-strength steel wire to improve the impact resistance of bad road conditions.

◆Reinforced bead and carcass design, excellent bearing performance.

◆Mine flower special tread formula design provides excellent cutting resistance and puncture resistance.

Main specifications and parameters of HD786G OTR tyres Haida tires HD786G 12R22.5 mining tires

Specification

| Hierarchy

| load index

| Speed level

| standard rim

| Section width(mm)

| Outer diameter (mm)

| design pattern Depth(mm |

12R22.5 | 18 | 152/149 | G | 9.00 | 300 | 1085 | 24 |

The difference between mining tires and ordinary tires

Mining tires are mainly used in open pit mines to deal with harsh roads, and the top carcass is thick, which is not suitable for long-distance running.

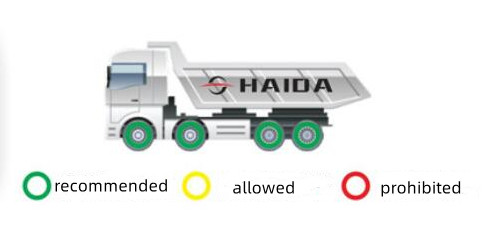

How to choose tires for mining engineering vehicles

For the mining engineering vehicles that must pass through it, the tire wear is the most troublesome thing for the driver. If you don't know the tire pattern performance, and blindly think that the famous brand is the best, it will only consume more money. on scrap tires.

The scientific, appropriate and correct selection of mining engineering vehicle tires will greatly improve work efficiency, reduce losses and troubles, and also greatly save costs. Generally, they are steel tires with large patterns. The general road conditions of the mine road are poor, the large pattern is more wear-resistant, the grip is stronger, and it is also resistant to stone trapping. The function of mining tires is that the degree of wear resistance is higher than that of ordinary tires, and the load capacity is super strong, but the speed level is low, and high-speed mode is absolutely not allowed. The pattern blocks of the tires are much larger than those of ordinary tires.

The function of mining tires is that the degree of wear resistance is higher than that of ordinary tires, and the load capacity is super strong, but the speed level is low, and high-speed mode is absolutely not allowed. The pattern blocks of the tires are much larger than those of ordinary tires.

It is the most intuitive to choose a tire with a thicker crown and a tire weight of more than 85 kg. Secondly, look at the gloss and fineness of the tire rubber, which is to distinguish whether the tire is made of original ecological rubber or reclaimed rubber. The tires made of the two raw materials are very different. Obviously, the glossiness is good and the tire quality is fine. The original ecological rubber or most of the original ecological rubber is used. If the tire quality is dark and rough, it means that too much reclaimed rubber is used.