In extreme environments, equipment failure is not an inconvenience. It is a mission risk.

Military and defense vehicles operate across deserts, mud, rock, snow, and unstable terrain. Tires are not just rubber components. They are load-bearing, impact-absorbing, traction-generating structural systems that determine mobility and survival capability.

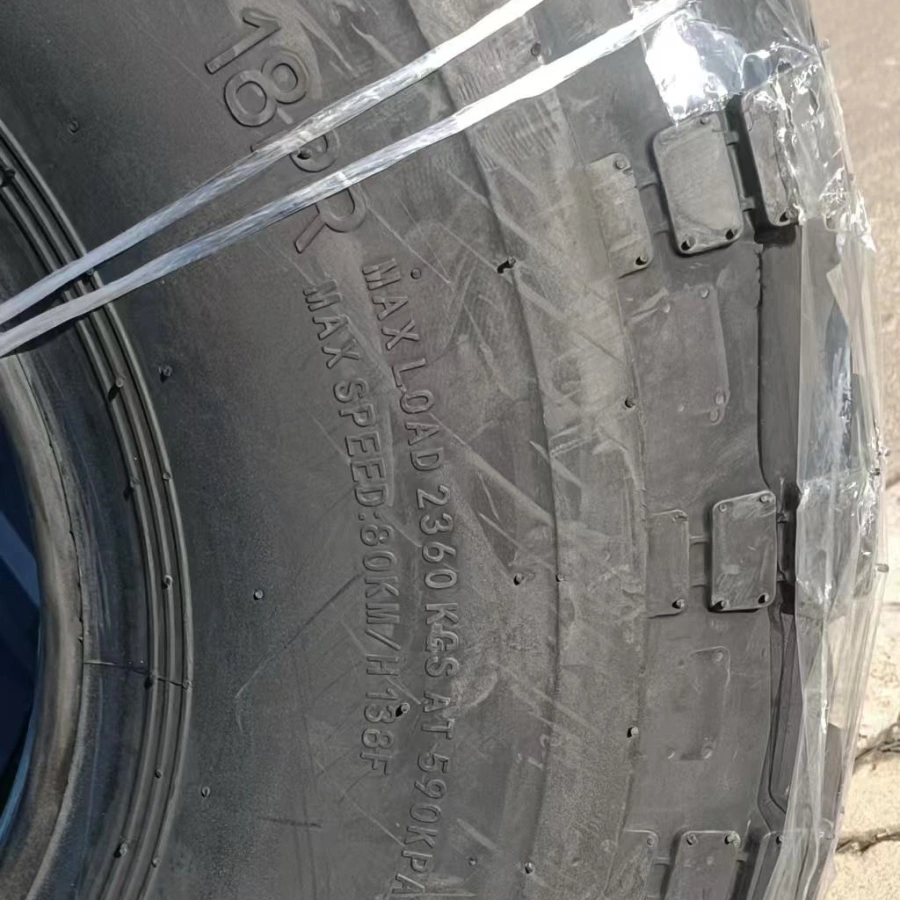

The Military Tire 13.00-18 (340-457) Reinforced Structure, weighing 63kg, is engineered for durability, stability, and long service life. With a reinforced carcass and thickened steel wire construction, this heavy-duty military tire exceeds industry standards and is approximately 10% heavier than many competing models — a deliberate design choice that reflects enhanced material density and structural strength.

High-quality military tires are currently shipping and ready for procurement. This article provides a comprehensive technical and practical overview of this product, including structure, materials, performance advantages, and application scenarios.

1. Product Overview: 13.00-18 (340-457) Military Tire

The 13.00-18 specification refers to:

13.00 inches section width

18 inches rim diameter

Metric equivalent: 340-457

This tire is commonly used for:

Military transport vehicles

Tactical support trucks

Armored logistics vehicles

Off-road engineering vehicles

Specialized defense machinery

At 63kg per tire, it surpasses standard civilian alternatives in structural mass and reinforcement integrity.

Weight in heavy-duty tires is not excess. It is reinforcement.

2. Why Military Vehicles Require Reinforced Tires

Military operations introduce extreme demands:

Heavy payloads

High torque output

Rough terrain impact

Prolonged off-road use

Temperature fluctuations

Extended idle-to-high-speed transitions

Civilian tires prioritize fuel efficiency and comfort.

Military tires prioritize durability and reliability under stress.

Failure is not acceptable in the field.

What is Royal Mile tire?

Royal Mile brand tire is typically positioned as a value-oriented tire line designed for practical, everyday driving. The name “Royal Mile” evokes endurance and distance—like the famous historic road in Edinburgh—but in the tire world it usually signals durability and mileage performance rather than luxury.

In most markets, Royal Mile tires are produced as budget or mid-range alternatives to premium global brands. They are commonly manufactured in Asia and distributed through regional wholesalers. The focus is on cost efficiency, stable tread wear, and acceptable all-season traction rather than high-speed or ultra-performance driving.

Technically speaking, these tires are generally radial construction (meaning the internal cord plies run perpendicular to the direction of travel), which improves ride comfort and fuel efficiency compared to older bias-ply designs. The tread compounds are formulated to balance wear resistance and grip, often optimized for urban roads and light highway use.

Royal Mile tires are typically used on passenger cars, compact SUVs, and light-duty vehicles. They are suitable for drivers who prioritize affordability, steady mileage, and basic safety compliance with standard road regulations. We have also made significant breakthroughs in military tires.

As with any tire brand, performance depends on the specific model, load rating, speed rating, and local road conditions. Choosing the correct size and specification always matters more than the logo on the sidewall.

3. Technical Specifications

Below is a general technical reference for the 13.00-18 military reinforced tire:

| Parameter | Specification |

|---|---|

| Tire Size | 13.00-18 (340-457) |

| Weight | 63 kg |

| Structure | Reinforced Bias Construction |

| Steel Wire | Thickened High-Tensile Steel |

| Ply Rating | Heavy-Duty Military Grade |

| Application | Off-road / Tactical / Transport |

| Tread Type | Deep Lug Aggressive Pattern |

| Load Capacity | Heavy Military Load Class |

| Sidewall | Reinforced Impact-Resistant |

| Rubber Compound | High Durability Military Compound |

Exact load rating and inflation pressure specifications can be customized based on vehicle requirements.

4. Reinforced Structure: Engineering Details

4.1 Thickened Steel Wire Belt

The core strength of this military tire lies in its thickened steel wire reinforcement.

Compared to standard commercial tires:

Steel cords are denser

Tensile strength is higher

Impact resistance is improved

Structural deformation is minimized

Steel wire reinforcement increases:

Puncture resistance

Sidewall stability

Load-bearing capacity

Long-term fatigue resistance

In harsh terrain, rocks do not negotiate. Steel reinforcement answers directly.

4.2 Heavy-Duty Bias Construction

Bias construction allows:

Stronger sidewalls

Better shock absorption

Improved durability on uneven terrain

While radial tires offer smoother highway performance, bias military tires are preferred for extreme off-road conditions due to structural rigidity.

4.3 10% Heavier Than Competitors

This tire weighs approximately 10% more than similar products in the market.

Why does that matter?

More weight in heavy-duty tires usually means:

Thicker rubber layers

Denser reinforcement

Stronger internal ply structure

Enhanced protection against cuts and impacts

Material density directly influences durability.

Lighter is not always better.

5. Tread Pattern Design

The 13.00-18 military tire features a deep, aggressive tread design optimized for:

Mud traction

Loose gravel grip

Sand mobility

Uneven terrain stability

Key design features:

Wide tread blocks

Deep groove channels

Self-cleaning pattern

Enhanced shoulder lugs

This ensures:

Strong forward traction

Reduced slippage

Improved braking control

Stability under torque

Mobility is survival in military operations.

6. High-Performance Rubber Compound

The rubber compound is engineered for:

Abrasion resistance

Heat resistance

Low cracking tendency

Extended tread life

Military tires must endure:

Long idle periods

Rapid acceleration

Load fluctuations

Harsh environmental exposure

The compound is formulated to resist:

Ozone damage

UV degradation

Surface cracking

Longevity reduces replacement frequency and operational downtime.

7. Application Scenarios

7.1 Tactical Military Transport Vehicles

Used in:

Troop carriers

Cargo transport trucks

Engineering support vehicles

Strong load capacity ensures safe transport under heavy equipment loads.

7.2 Off-Road Military Operations

In desert or mountainous terrain, traction determines maneuverability.

Deep lug design ensures:

Grip on sand

Control on rocks

Stability in mud

7.3 Industrial and Defense Engineering Vehicles

Also suitable for:

Construction equipment

Emergency response vehicles

Oil field support vehicles

Mining trucks in rugged terrain

Heavy reinforcement ensures stable operation.

8. Advantages Over Standard Commercial Tires

| Feature | Military 13.00-18 | Standard Commercial |

|---|---|---|

| Weight | 63kg (10% heavier) | Lighter |

| Reinforcement | Thickened steel wire | Standard reinforcement |

| Sidewall Strength | High impact resistance | Moderate |

| Terrain Capability | Extreme off-road | Mixed |

| Durability | Long lifespan | Shorter lifespan |

Military-grade design focuses on durability first.

9. Performance in Extreme Conditions

9.1 High Temperature Operation

Reinforced structure resists heat buildup under load.

9.2 Cold Climate Operation

Flexible compound reduces cracking in low temperatures.

9.3 Heavy Load Stability

Strong carcass reduces deformation under high weight.

Consistency is key in tactical mobility.

10. Quality Control and Manufacturing Standards

High-quality military tires undergo:

Raw material inspection

Steel wire tensile testing

Dynamic balance testing

Load endurance testing

Air retention testing

Impact resistance testing

Manufacturing precision ensures structural integrity.

A military tire must not fail under pressure — literally.

11. Logistics and Shipping

This military tire is currently in production and shipping.

Advantages include:

Bulk supply capability

Stable production capacity

Reliable export packaging

Global shipping support

Each tire is securely packed to prevent deformation during transport.

12. Procurement Advantages

Choosing a reinforced 63kg military tire provides:

Extended service life

Lower long-term replacement cost

Reduced maintenance downtime

Improved vehicle stability

Enhanced operational reliability

In procurement decisions, total lifecycle cost matters more than initial price.

13. Why Weight Reflects Quality in Military Tires

In high-performance automotive sectors, lighter can mean faster.

In military and heavy-duty environments, heavier often means stronger.

The 10% additional weight reflects:

Thicker tread depth

Denser internal structure

Greater steel reinforcement

Increased puncture protection

Mass equals durability in extreme conditions.

14. Maintenance Recommendations

To maximize tire life:

Maintain correct inflation pressure

Conduct regular tread inspection

Rotate tires periodically

Avoid prolonged overload

Store in dry, shaded conditions

Proper maintenance extends performance.

15. Competitive Advantage in Global Market

The 13.00-18 reinforced military tire stands out because:

It exceeds average competitor weight

Uses thickened steel wire

Is engineered for heavy tactical use

Offers durable performance

Is available for immediate shipment

Buyers seeking high-strength, reliable military tires benefit from choosing products designed beyond minimum specification requirements.

16. Customization Options

Available upon request:

Custom tread pattern

Reinforced sidewall thickness adjustments

Military-specific load ratings

Branding and marking customization

Bulk packaging solutions

Flexible production supports varied defense and industrial needs.

17. Long-Term Operational Benefits

For military and industrial fleet operators, tire durability directly impacts:

Mission reliability

Maintenance budgets

Operational readiness

Vehicle safety

Replacing fewer tires reduces:

Downtime

Labor costs

Supply chain dependency

Durability compounds over years.

18. Conclusion

The Military Tire 13.00-18 (340-457) with reinforced structure and thickened steel wire is engineered for high-demand environments.

Weighing 63kg, approximately 10% heavier than comparable models, it represents enhanced structural integrity and material density.

It delivers:

Strong load capacity

Superior puncture resistance

Deep traction performance

Long operational lifespan

Reliable durability in extreme terrain

For tactical vehicles, industrial heavy equipment, and off-road military transport, this high-quality reinforced military tire is currently shipping and available for procurement.

When durability matters more than comfort,

When reliability matters more than cost cutting,

When strength determines success —

Choose reinforced structure.

Choose thickened steel wire.

Choose performance built for mission-critical environments.

High-quality military tires are ready for dispatch.

Bulk orders are welcome.

Engineered strength, now available.