As transportation costs rise and sustainability becomes a global priority, tire retreading is no longer a niche practice—it is a strategic choice. At the heart of successful retreading lies one critical factor: tire retreading material quality.

High-performance tire retreading materials directly determine tread life, safety, rolling resistance, and long-term operating cost. Poor materials lead to early wear, delamination, and customer complaints. High-quality materials, by contrast, can deliver performance comparable to new tires at a fraction of the cost.

Our factory specializes in manufacturing a full range of tire retreading materials, covering multiple specifications, tread patterns, and compound formulations. With strict quality control and a guaranteed service life of up to 100,000 km, our products are designed for reliability, consistency, and real-world performance.

What Are Tire Retreading Materials?

Tire retreading materials are the rubber compounds and supporting components used to replace worn tread on used tire casings. Instead of discarding the entire tire, retreading restores traction and load performance while reusing the original casing.

Core retreading materials typically include:

Precured tread rubber

Cushion gum (bonding rubber)

Repair rubber and patches

Sidewall rubber compounds

Envelope and curing accessories

Among these, precured tread rubber and cushion gum play the most critical role in determining mileage, adhesion strength, and safety.

Why High-Quality Tire Retreading Material Matters

Retreading is only as good as the materials used. Industry data shows that over 70% of retreading failures are caused not by the casing, but by poor material performance or improper bonding.

High-quality tire retreading materials provide:

Strong adhesion between tread and casing

Uniform wear across the tread surface

Heat resistance under long-distance driving

Reduced risk of tread separation

Stable performance under heavy loads

With proper retreading materials, a retreaded tire can achieve 90–95% of the mileage of a new tire, while costing significantly less.

Our Tire Retreading Material Product Range

Our factory produces a complete range of tire retreading materials, suitable for different vehicles, road conditions, and operating environments.

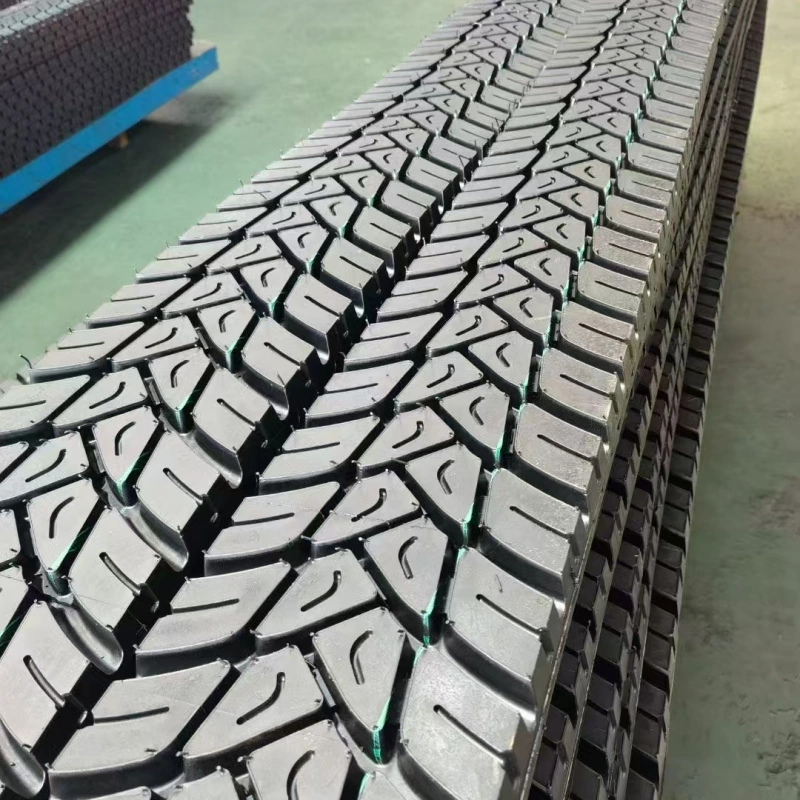

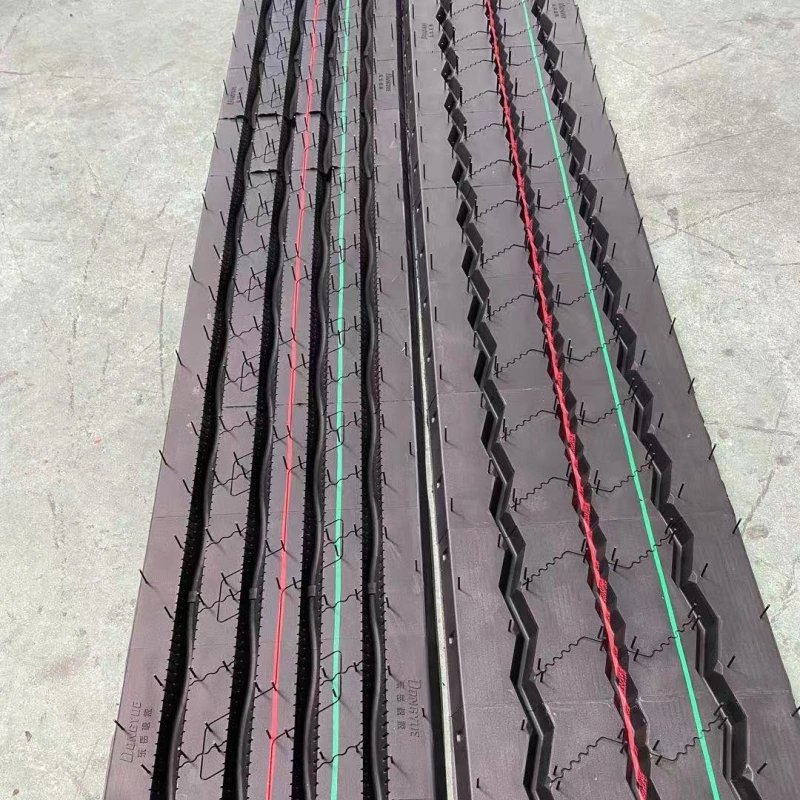

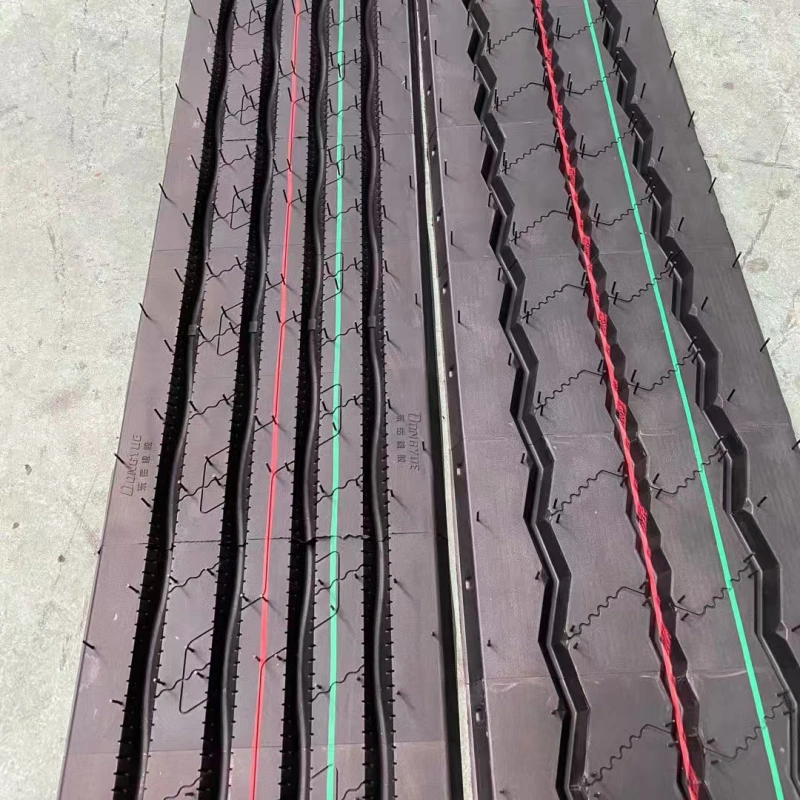

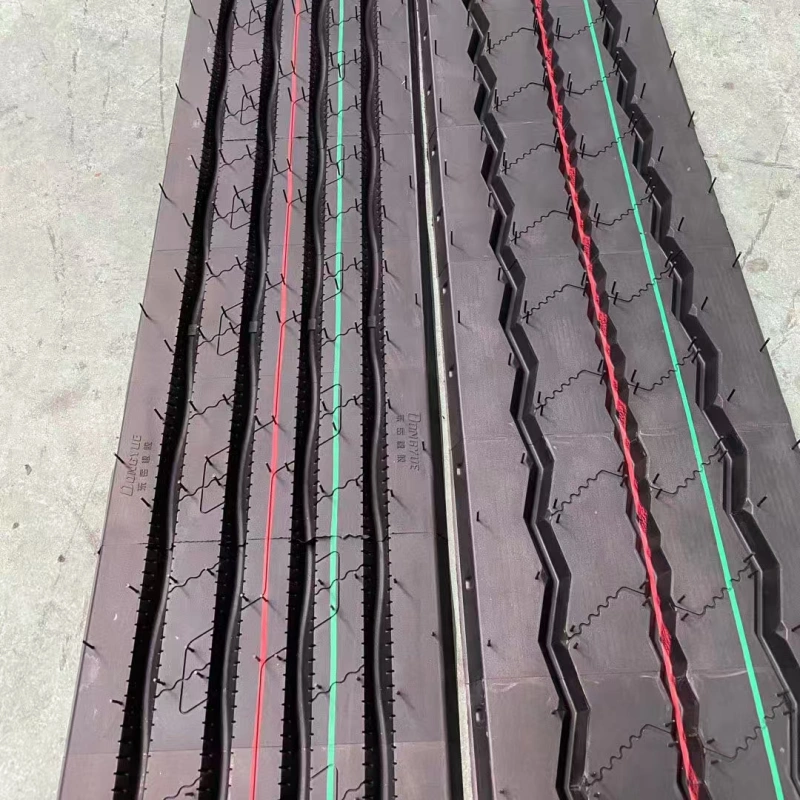

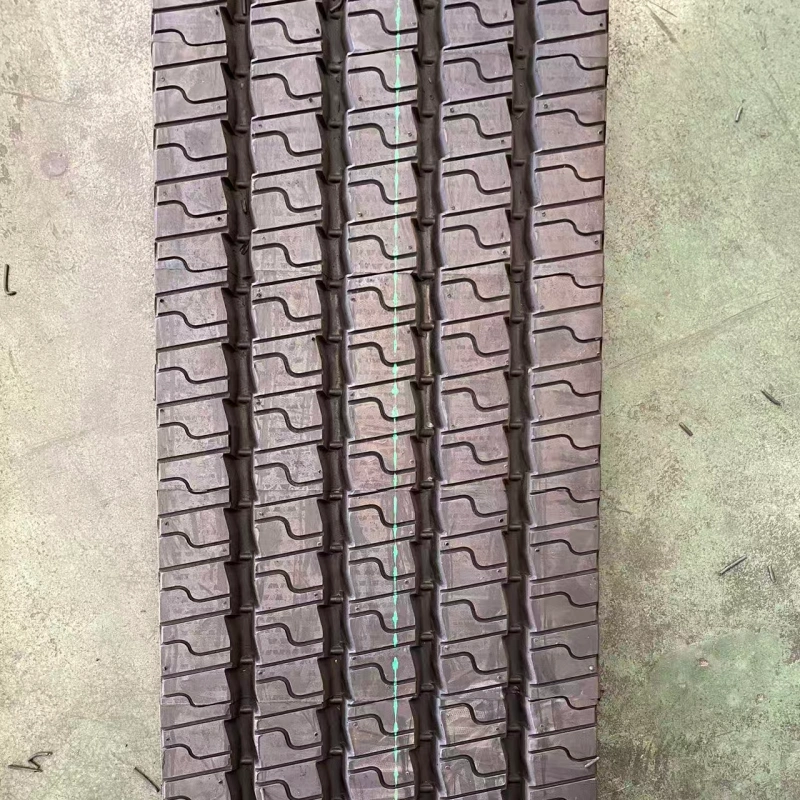

Precured Tread Rubber

We manufacture precured tread rubber in multiple designs and rubber formulations, suitable for:

Trucks and buses

Commercial fleets

Long-haul transportation

Regional and mixed road use

Available tread patterns include rib, lug, block, and mixed designs, optimized for traction, mileage, and noise reduction.

Cushion Gum

Cushion gum is the bonding layer between the tread rubber and tire casing. Our cushion gum offers:

Excellent tack and flow

Strong bonding strength

Uniform curing behavior

Resistance to heat and fatigue

This ensures reliable adhesion during both precure and mold cure retreading processes.

Repair and Sidewall Compounds

Our repair materials are designed for casing preparation and minor damage repair, maintaining casing integrity without compromising safety.

Technical Advantages of Our Tire Retreading Materials

Long Mileage Performance

Our rubber compounds are formulated for high abrasion resistance, enabling retreaded tires to reach up to 100,000 km under normal operating conditions. This mileage guarantee is based on controlled compound formulation and consistent production.

Strong Adhesion Strength

Bonding strength between tread and casing is critical. Our cushion gum and tread base rubber achieve high peel strength, reducing the risk of separation even under continuous high-temperature operation.

Heat and Fatigue Resistance

Long-distance and heavy-load driving generate heat. Our materials are tested for heat buildup control, reducing internal stress and extending service life.

Stable Quality Consistency

We use standardized mixing, extrusion, and curing processes to ensure batch-to-batch consistency, which is essential for large retreading operations.

Technical Specification Overview

| Item | Specification |

|---|---|

| Product Type | Tire Retreading Material |

| Main Products | Precured tread rubber, cushion gum |

| Rubber Type | Natural rubber + synthetic rubber |

| Tread Width Range | Multiple specifications available |

| Tread Thickness | Customized |

| Mileage Guarantee | Up to 100,000 km |

| Adhesion Strength | High peel resistance |

| Heat Resistance | Suitable for long-haul use |

| Application | Truck, bus, commercial vehicles |

| OEM / Customization | Available |

Manufacturing Capability and Quality Control

As a direct tire retreading material factory, we control every step of production:

Raw material selection and formulation

Rubber mixing and compound optimization

Extrusion and tread pattern shaping

Precure vulcanization

Physical property testing

Final inspection and packaging

Each batch undergoes testing for hardness, tensile strength, elongation, abrasion resistance, and adhesion performance. This systematic control is the foundation of our 100,000 km quality guarantee.

Application Scenarios

Commercial Truck Fleets

Fleet operators benefit from lower tire cost per kilometer while maintaining safety and performance standards.

Long-Haul Transportation

Our tread compounds are designed for stable wear and heat resistance over extended highway driving.

Logistics and Distribution

Consistent traction and mileage help reduce downtime and maintenance frequency.

Regional and Mixed Road Use

Optimized tread designs provide balanced performance on highways, urban roads, and secondary routes.

Cost Efficiency and Sustainability Benefits

Retreading with high-quality materials delivers clear economic and environmental advantages:

30–50% cost savings compared to new tires

Reduced raw material consumption

Lower carbon footprint per kilometer

Extended casing utilization

In many markets, retreading is not just economical—it is a responsible choice aligned with sustainability goals.

Common Problems Caused by Low-Quality Retreading Materials

Using inferior materials often leads to:

Premature tread wear

Tread lifting or separation

Uneven wear patterns

Increased heat buildup

Customer complaints and warranty claims

These problems erase cost savings and damage business reputation. Quality materials are not an expense—they are insurance.

Customization Options

We understand that different markets and fleets have different needs. Our factory offers:

Multiple tread patterns

Customized tread widths and thickness

Compound tuning for specific road conditions

Private labeling and OEM support

Bulk supply for retreading plants

Customization ensures optimal performance and stronger brand differentiation.

How to Choose the Right Tire Retreading Material Supplier

When selecting a supplier, buyers should focus on:

Proven manufacturing experience

Clear technical specifications

Consistent quality control

Real mileage data, not marketing claims

Reliable after-sales support

A supplier willing to stand behind a 100,000 km guarantee is confident in both product and process.

Market Outlook for Tire Retreading Materials

Global demand for tire retreading materials continues to grow as fuel prices rise and sustainability regulations tighten. High-quality retreading materials are increasingly favored by fleets seeking predictable operating costs and reduced environmental impact.

Manufacturers that focus on compound performance, consistency, and real mileage will lead this market.

Conclusion

Tire retreading material quality determines the success of every retreaded tire. With full specifications available, strict quality control, and a guaranteed service life of up to 100,000 km, our factory provides reliable, high-performance solutions for modern retreading operations.

We are a factory from China specializing in tire retreading materials. We produce high-quality retreaded tire treads.

By choosing good-quality tire retreading materials, businesses reduce costs, extend tire life, and deliver safer performance on the road. In retreading, the smartest savings start with the right material